Contents

Our temporary suspended platforms (TSP For Temporary Suspended Platform within the meaning of standard EN1808) make it possible to carry out high-rise work on construction and/or intervention facades in the construction sectors. Building, Industry, the elevator operator, of Infrastructure, of Sports and Entertainment and of Wind power. Their elevation is possible thanks to winches which are located on both ends of the platforms and to the cables which allow their elevation thanks to a suspension system.

“Platform” safely

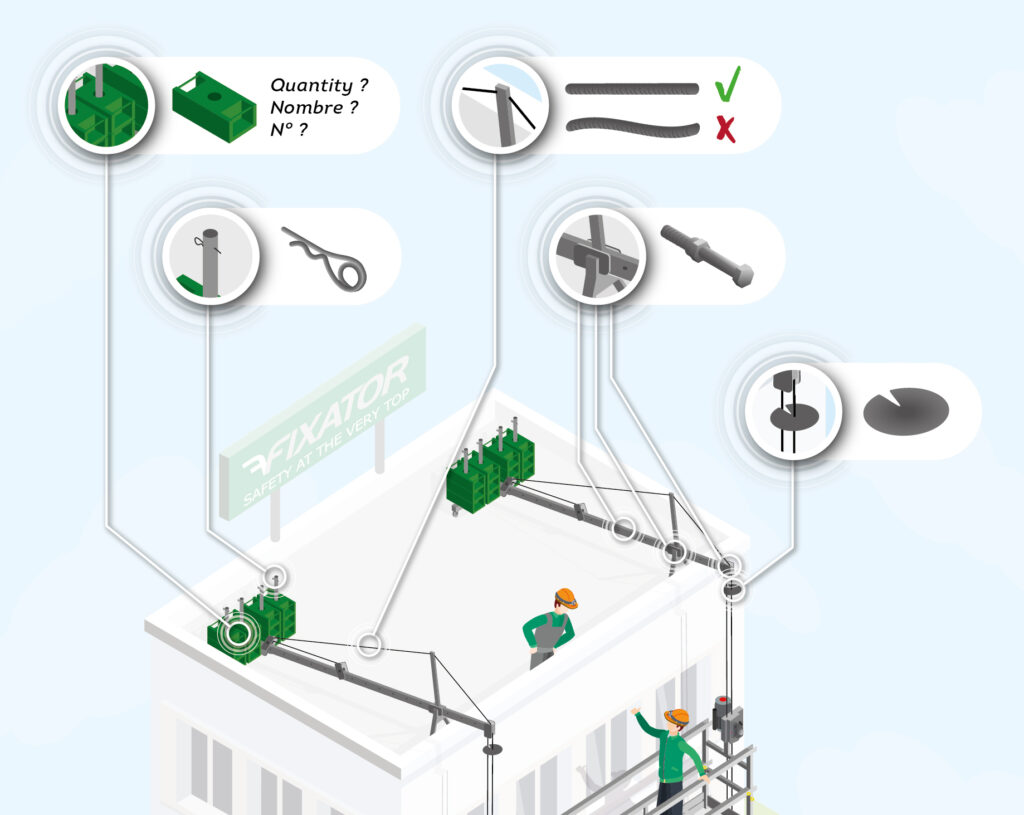

Apart from regulated security measures, carrying out a daily check of the suspended equipment by a trained person is essential !

We recommend that the operator carry out a daily visual inspection of all elements that influence the operational safety of the platform, thus making it possible to detect possible deterioration, due to wear and/or vandalism, likely to create dangers in the workplace. Furthermore, please refer to the elements of the inspection sheet that we make available on our platforms (within the control box) before starting the work. The operator can also consult the inspection recommendations transcribed in our instruction manuals.

Check and test the equipment every day!

The Clashes

We advise you to check:

- The counterweight – lock and exact number;

- The slings – are they tight?

- The end stopss and the screw (on the suspension beams) – are they all present?

The platforms

We advise you to check:

- The winch cables – must not be rusted, untwisted, crushed, pinched;

- L'Anti fall -functionality test;

- The winches – check the fixings;

- The winch covers – are they positioned correctly?

- The electrical outlets - lockdown;

- The cables – make sure they are not crushed;

- The technical characteristics indicated on the label FIXATOR – are they still readable?

- THE "electric punches“ (from the box and the button box) – do they work correctly?

- The counterweight on the cables

- security , THE pins, THE pins and the screw - are they all present?

Estimated time for platform checkpoints is 5 min!

In the event of a malfunction – How to proceed?

- Prevent use of the platform by removing the power plug;

- Inform the Site Manager;

- Record the incident in the maintenance log.