Contents

VIDEO: Suspended circular cradle in operation for cupola maintenance

VIDEO: Suspended circular nacelle in operation for cupola furnace maintenance

The need

Supply of a lifting device for underground access to cupolas for maintenance purposes.

Lifting capacity of 500 kg.

The customer

EJ Picardie, the foundry of the EJ Group, world leader in the design, production and distribution of access solutions for water, sewer, drainage, telecommunications and service networks.

The solution

Main product:

The circular flying pod

2 mechanically-welded steel 1m-diameter suspended circular platforms with galvanized finish, providing access to the 2 foundry cupolas for maintenance. Capacity for 2 people or 240 kg according to EN1808: 2015 and equipped with:

- Lifting gate for operator access;

- Expanded metal protective roof. Canopy can be detached from the nacelle (for emergency use);

- 3 adjustable stabilizers with wheels at the bottom;

- Expanded metal floor to allow partial evacuation of rubble, and central opening for various hoses (thermal lance, jackhammer);

- Securichute 600 overspeed – 600 kg capacity and spring reel for the safety cable.

Hanging system:

Translation carts

2 translation trolleys motorized with a capacity of 500 kg positioned on IPE profiles allowing the positioning of the nacelles above the cupolas.

The gondolas are stored apart when not in use.

Lifting gear:

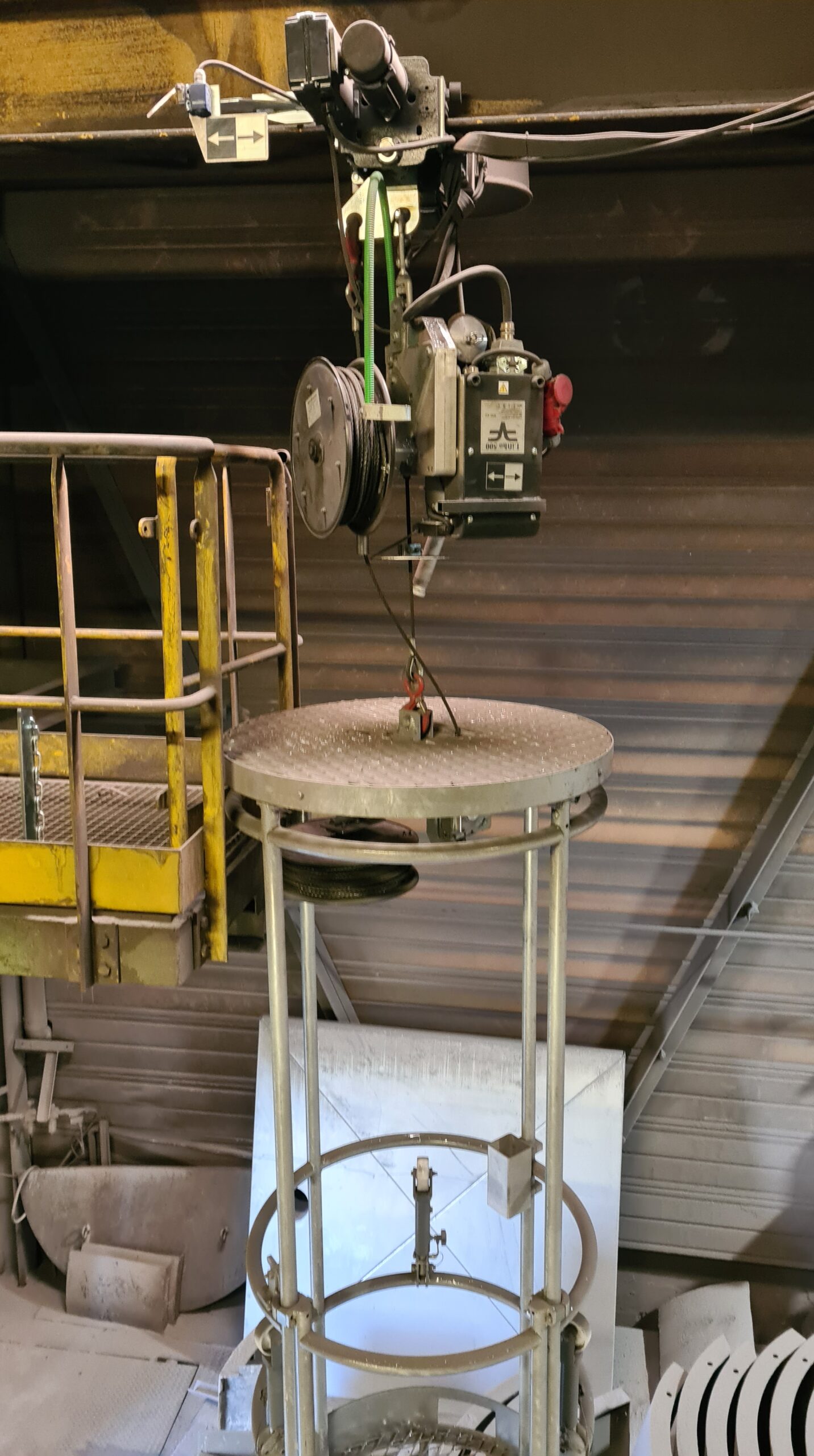

Liftho 500 winch

Liftho 500 people lifting winch (for custom projects; the Liftho range is available in 600, 800 and 1000 kg as standard), 400V, three-phase, 50/60Hz, attached at the top to a motorized translation cart on a building’s IPE rail and equipped with all the safety features in compliance with EN1808:

- Spring reel to store the working cable (Ø8.3 mm);

- Limit switch;

- End limit switch;

- Electronic overload with continuous on-board load measurement and audible and visual overload warning;

- Slack wire-rope;

- Flashing light indicating the movement of the assembly;

- 5-button radio control: Up/Down/Right Shift/Left Shift/Emergency Stop.

Additional information and thanks

One wired emergency control box emergency to allow remote control in the event of operator failure.

Travel speed: approx. 5 m/min

This design was carried out by our business manager Emmanuel Lusseau.

We would also like to thank EJ Picardie for the trust and sharing of photos.

Suspended cradle and view of the safety fall arrester Securichute

View of the Securichute 600 under the roof of the circular flying pod

Raising from the cupola furnace

Descent into the cupola furnace